- Homepage

- Manufactoring process

Manufactoring process

The production process from the initial design to the production of color samples involves many technicians and departments. Each stage is subject to multiple control criteria, with the utmost attention to quality standards and the smallest of details.

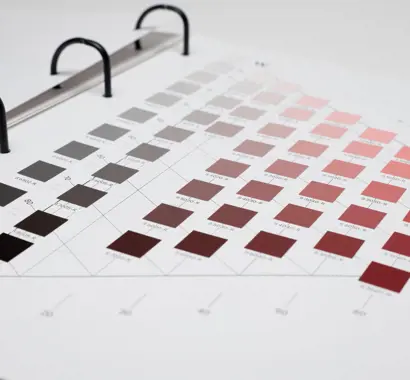

Color matching

Starting with a physical or digital standard provided by the client, our colorists match and verify the color to obtain an accurate result.

Contact us for more informations

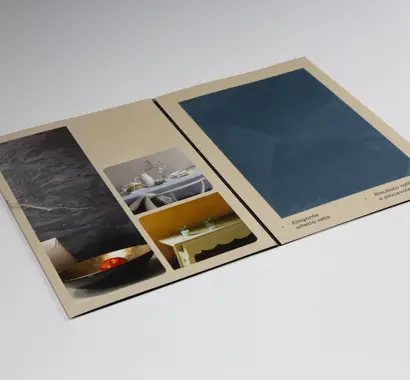

Color approval

The color matching result, or original product application, is submitted to the client with the original color reference for evaluation and approval.

Contact us for more informations

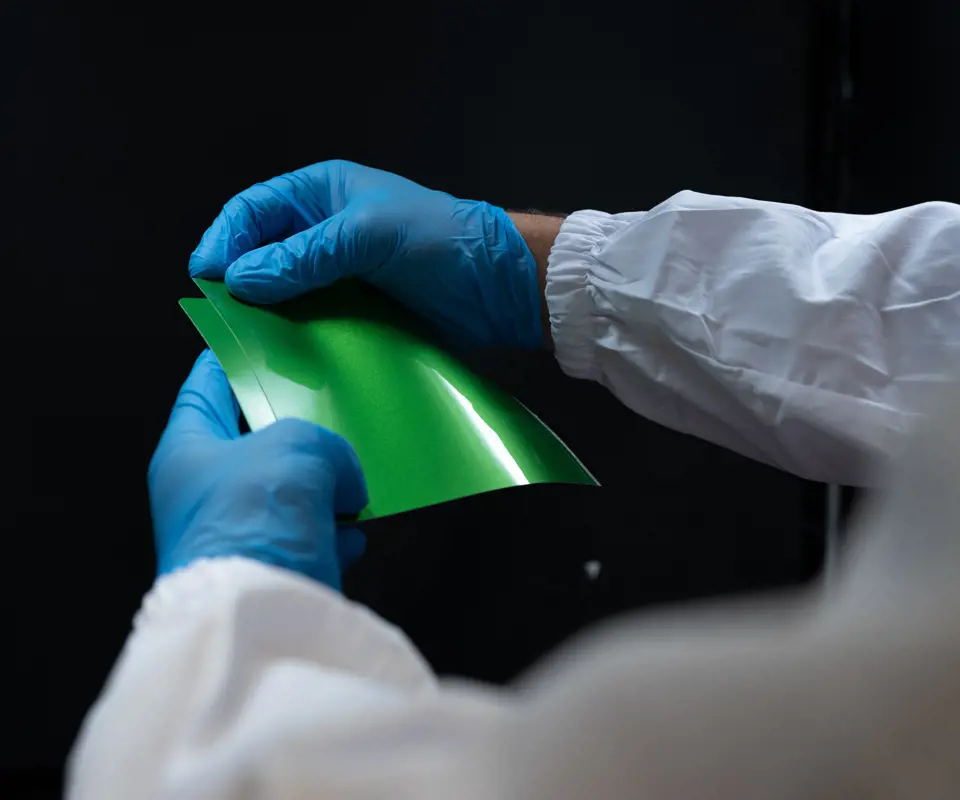

Color application

The paints are applied by coating, spraying or by manual application.

Contact us for more informations

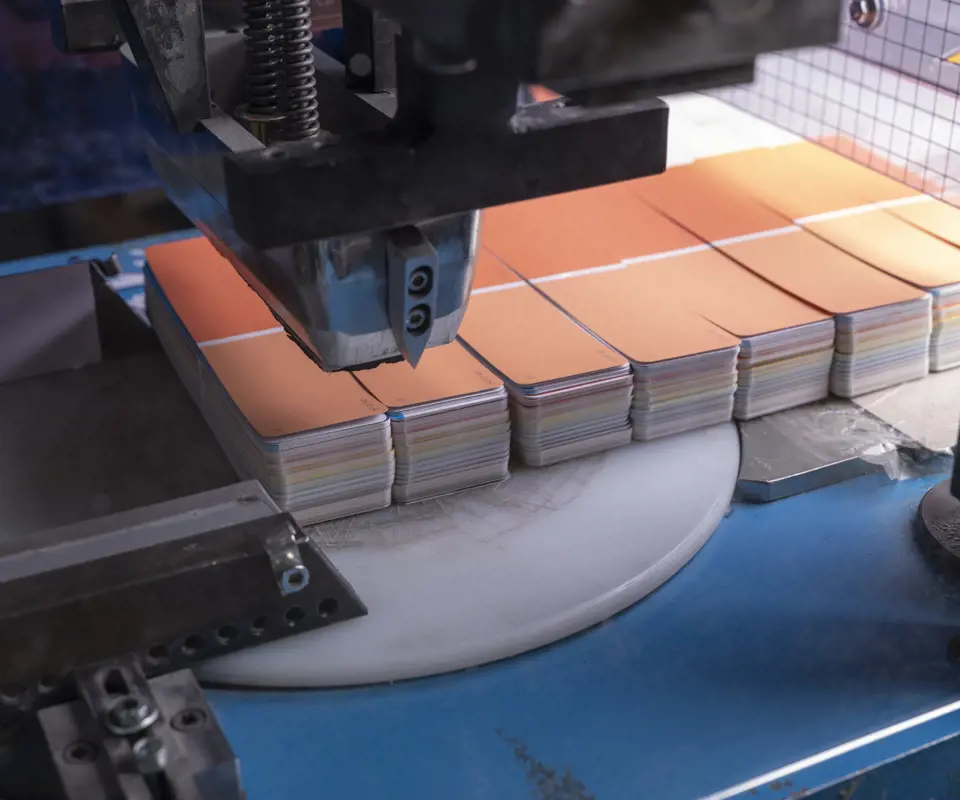

Printing

The printed presentation portion of the color samples, be that in the form of brochures, fan deck covers, color codes, etc., is prepared in parallel to the production of the colors. Starting from digital print files provided by the customer, CPE produces blueprints for approval by the customer before completing the printing of the items. The printing methods adopted are offset, digital and screen printing.

Contact us for more informations

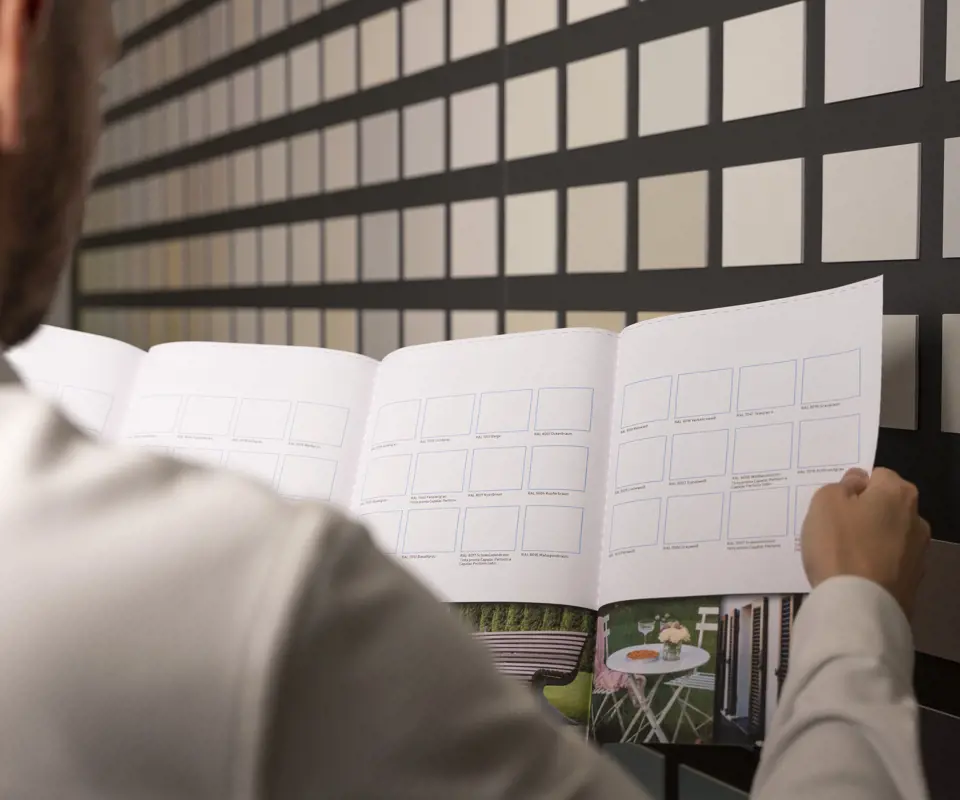

Quality control

Colors and print undergo several inspections to ensure they meets the customer's requirements.

Contact us for more informations

Assembly and packaging

Once approved, the colors are applied to sheets of various materials, which are then transformed into the final products through cutting or die-cutting, gluing, collating, and assembling with printed presentations according to the type of product to be made. The finished products are then packaged safely in the manner specified by the customer and shipped to destination.

Contact us for more informations

Our products

CPE works with its customers to create different color samples such as:

Services

In addition to the production of color sampling, CPE provide its customers with a range of services.

Formulation

We specialize in the formulation of solid, metallic, mica and pearlescent colors.

Discover more

Storage & Assembly

We have extensive storage facilities for your products.

Discover more

System Updating

We update your color systems by incorporating the new colors that are launched in the market.

Discover more

Mailing service

We ship your products worldwide.

Discover more